Lathe Machine A Simple Guide to Understanding and Using It

Lathe machine is one of the most important tools in workshops and factories. Lathe machine helps to shape, cut, and polish different materials like metal, wood, and plastic. People use lathe machines to make parts for machines, furniture, and many other things. Learning how to use a lathe machine can make your work easier and faster. It is also very useful for students and beginners who want to learn mechanical skills. A lathe machine works by spinning the material while a sharp tool shapes it. This process can make very precise and smooth shapes. Many small and big industries use lathe machines every day. Whether you want to make toys, car parts, or tools, lathe machine can help you do it with accuracy and safety. Understanding lathe machine basics is the first step for anyone who wants to work in manufacturing or mechanical jobs.

Using a lathe machine may seem difficult at first, but it is easy to learn with practice. Lathe machines come in different types like engine lathe, wood lathe, and CNC lathe. Each type has a special use. For example, a wood lathe is perfect for making bowls, sticks, or furniture legs, while a metal lathe is used for making strong machine parts. Safety is very important while using a lathe machine. Always wear protective glasses and keep your hands away from moving parts. You should also know about speed, feed, and cutting tools to get the best results. Many schools and training centers teach students how to use lathe machines step by step. Once you learn, you can make many creative and useful items. A lathe machine is not only a tool but also a way to improve your skills and create things with precision.

How a Lathe Machine Works

The basic working of a lathe machine is simple but very effective. First, the material is fixed on the spindle. The spindle spins the material at different speeds depending on the type of work. Then a sharp cutting tool is applied to the spinning material to shape or cut it. This process allows the operator to make objects with high precision and smooth finish. Different operations like turning, facing, threading, and drilling can be done using a lathe machine. The cutting tool moves in a controlled way to remove extra material. With practice, anyone can use a lathe machine to make professional-quality parts and designs.

Types of Lathe Machine

There are several types of lathe machines, and each has a special use.

1. Engine Lathe: This is the most common lathe machine used in many workshops. It can perform turning, facing, and threading operations on metal parts.

2. Wood Lathe: This lathe is designed for shaping wood. It is perfect for making furniture, bowls, and decorative sticks.

3. CNC Lathe: CNC means Computer Numerical Control. This lathe is controlled by a computer. It is used in industries for making precise machine parts automatically.

4. Turret Lathe: This type of lathe has a turret that can hold multiple tools. It is used for high-speed production and reduces the time needed for changing tools.

5. Toolroom Lathe: Toolroom lathe is used for making small and precise parts. It is often used in laboratories and training workshops.

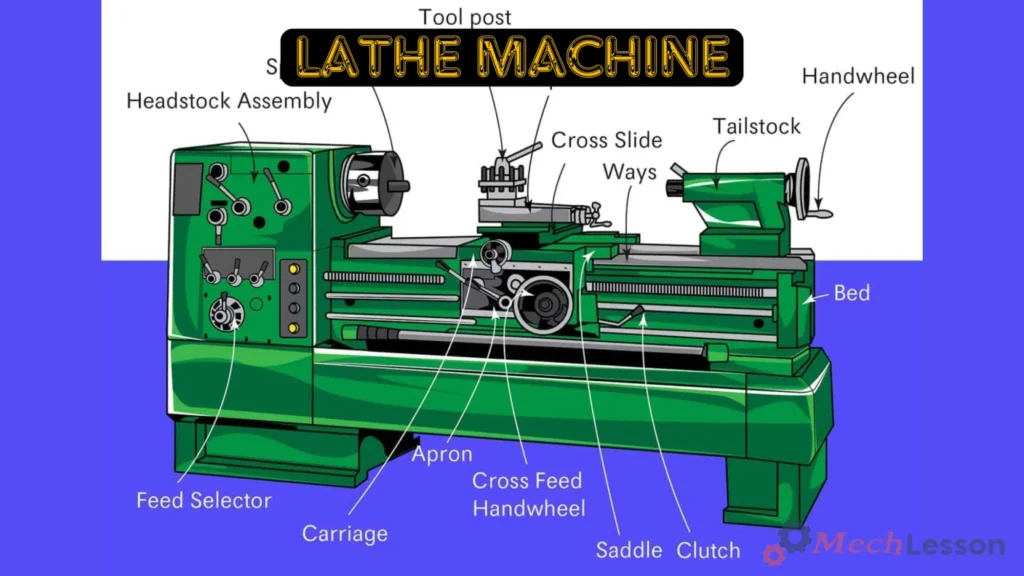

Important Parts of a Lathe Machine

A lathe machine has many parts, and each part plays a special role.

1. Bed: The bed is the base of the lathe. It holds all other parts and keeps them aligned.

2. Headstock: The headstock contains the spindle, which spins the material. It also holds gears to change speed.

3. Tailstock: The tailstock is used to hold long pieces of material and support them while spinning.

4. Carriage: The carriage moves the cutting tool along the material. It controls the movement of the tool in a precise way.

5. Tool Post: The tool post holds the cutting tool in position. You can change the tool depending on the work.

6. Lead Screw: The lead screw helps in threading and precise movement of the carriage.

7. Chuck: The chuck holds the material tightly. It comes in different types like 3-jaw, 4-jaw, or collet chuck.

Basic Operations of a Lathe Machine

Lathe machines can perform many operations. Some common operations are:

1. Turning: This is the process of reducing the diameter of a material to make it round.

2. Facing: Facing makes the end of the material flat and smooth.

3. Drilling: A drill bit can be attached to the lathe to make holes in the material.

4. Threading: Threading creates screw threads on the material.

5. Knurling: Knurling makes a rough pattern on the surface for better grip.

6. Taper Turning: Taper turning creates a cone-like shape on the material.

Safety Tips While Using a Lathe Machine

Using a lathe machine can be dangerous if you don’t follow safety rules. Always wear protective glasses and gloves. Keep hair and loose clothes away from moving parts. Never touch the spinning material with bare hands. Make sure the workpiece is fixed tightly in the chuck. Always use the right cutting tool and speed for the material. Do not leave the machine running unattended. Safety is very important to avoid injuries and accidents while working with a lathe machine.

Choosing the Right Lathe Machine

Choosing a lathe machine depends on your needs. If you want to work at home or in a small workshop, a small wood lathe or mini metal lathe is good. For industrial work, CNC lathe or engine lathe is better. Consider the size of material you will work with, the type of operations, and your budget. A good lathe machine should be stable, durable, and easy to maintain. Research different models, read reviews, and compare prices before buying.

Tools and Accessories for Lathe Machine

Lathe machines need tools and accessories to work properly. Some common tools include:

1. Cutting Tools: These are used to shape or cut the material. High-speed steel or carbide tools are common.

2. Tool Holders: Tool holders fix the cutting tool in the correct position.

3. Measuring Tools: Calipers, micrometers, and gauges are used to measure the workpiece accurately.

4. Chucks and Collets: Chucks and collets hold the material securely during work.

5. Centers: Centers support the material at the tailstock for long or round workpieces.

Maintenance of a Lathe Machine

Proper maintenance of a lathe machine keeps it working efficiently for a long time. Always clean the machine after use to remove dust and metal chips. Lubricate moving parts regularly to reduce wear and tear. Check the alignment of the spindle, carriage, and tailstock. Replace worn-out tools and parts immediately. Regular maintenance ensures safety, accuracy, and better performance of the lathe machine.

Lathe Machine Projects for Beginners

Beginners can try simple projects to learn lathe operations. Some easy projects are:

1. Wooden pen or pencil holder

2. Small metal rods for DIY projects

3. Decorative wooden bowls

4. Screw threads on bolts

5. Furniture legs or candle holders

These projects help beginners practice turning, facing, and drilling operations. With experience, you can move to more complex projects like machine parts or artistic designs.

Benefits of Using a Lathe Machine

Lathe machines have many benefits. They help in making accurate and smooth parts quickly. They save time and effort compared to manual methods. Lathe machines can work on different materials like metal, wood, and plastic. They are useful for learning mechanical skills and creating professional-quality items. Using a lathe machine improves precision, productivity, and creativity in workshops, industries, and even home projects.

Advanced Lathe Machine Features

Modern lathe machines have many advanced features. CNC lathes use computers to control speed, tool movement, and design. Some lathes have digital readouts to show exact measurements. Automatic feed and coolant systems make work easier and safer. These advanced features help in high-volume production, better accuracy, and reduced manual effort.

Lathe Machine in Education

Many schools, colleges, and technical institutes use lathe machines for teaching. Students learn basic operations, safety rules, and measurement skills. Lathe machines help students understand mechanical principles practically. This knowledge is useful for careers in engineering, manufacturing, and technical work. Hands-on experience with a lathe machine prepares students for real-world industrial tasks.

Lathe Machine in Industries

Lathe machines are widely used in industries like automotive, furniture, electronics, and aerospace. They help in making machine parts, shafts, bolts, and decorative items. Industries use lathe machines for high-volume and precise production. CNC lathe machines are especially useful in industries for mass production with minimal human error. Using lathe machines increases efficiency, reduces cost, and improves quality in manufacturing.

Common Problems and Solutions in Lathe Machine

While using a lathe machine, some common problems may occur. These include vibration, uneven cutting, tool wear, and poor finish. Vibrations can be reduced by proper alignment and using a stable base. Uneven cutting may happen due to dull tools or wrong speed. Regularly sharpening cutting tools ensures better performance. Cleaning and lubrication prevent rust and wear. Understanding these problems and solutions helps in safe and efficient lathe operation.

Future of Lathe Machine

With modern technology, lathe machines are becoming more advanced. CNC and smart lathes are widely used for precise and automated production. Learning lathe machine skills is valuable for future jobs in engineering, manufacturing, and robotics. The demand for skilled operators and technicians will continue to grow. Lathe machines will remain a key tool in workshops and industries worldwide.

Conclusion

Lathe machine is a very useful tool for shaping, cutting, and polishing materials. It is important in workshops, industries, and educational institutes. Learning to use a lathe machine improves skills, accuracy, and creativity. From simple wood projects to complex metal parts, lathe machines make work faster and precise. Safety, maintenance, and the right tools are key to getting the best results. Beginners and professionals alike can benefit from using a lathe machine for practical and industrial work.

FAQs

Q1: What is the main use of a lathe machine?

A lathe machine is used to shape, cut, and polish materials like metal, wood, and plastic.

Q2: Is a lathe machine easy to learn for beginners?

Yes, with practice and basic guidance, beginners can learn to use a lathe machine safely.

Q3: What types of materials can a lathe machine work on?

A lathe machine can work on metal, wood, plastic, and other soft and hard materials.